Textile Rope Clutch

Unlike conventional clutches the Constrictor® system does not crush the rope between two metal surfaces. Instead, the loaded rope is held securely in a textile sleeve, itself attached to a base unit. The rope runs freely through the sleeve in one direction, but is gripped instantly when running out in the opposite direction. This patented “constrictor effect”, provides greater holding power as the load increases.

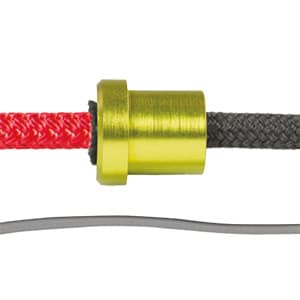

Bi-conical titanium ring

The patented textile sleeve element is locked in place between a titanium ring and the base unit. The unique conical geometry allows easy insertion of the rope, and ensures that the sleeve is perfectly integrated with the alloy base unit in supporting the applied load.

Controlled holding power

Pulling on the Dyneema® lanyard retracts the sleeve, relaxing the grip on the rope and allowing it to run freely in either direction. The lanyard can be fixed in the V-notch of the base unit to hold the Constrictor® in the open position. Releasing the lanyard allows the sleeve to be drawn to its extended position by a shock cord, constricting the rope in a firm, secure grip.

Anatomy of the Constrictor

Stronger and lighter - Twice the holding power and a third of the weight of conventional rope clutches.

Release under load - The line can easily be released under load without the use of a winch simply by pulling the lanyard.

Release under load - The line can easily be released under load without the use of a winch simply by pulling the lanyard.

Non destructive - The textile sleeve closes like a constrictor on the line. The extraordinary grip is the result of fibre-to-fibre contact that is far less aggressive than a traditional metal cam, and much more effective.

Structural integration - The Constrictor® is also available in a version suitable for structurally integrated installations. Instead of the notched alloy base unit, the sleeve is supplied with an alloy mounting collar that can be built into a suitably reinforced bulkhead or a customised base fitting.

Remote release - The Dyneema® lanyard can be extended for remote release; for example, to lock a halyard or reefing line to reduce spar compression and minimise rope creep.

Technora® aramid textile sleeve

- Braid Orientation: Cousin Trestec’s experience and expertise in rope manufacture guided the development of the critical braiding angle to maximise grip and minimise slippage.

- Fibre Assembly: Extensive knowledge of fibres combined with laboratory and field testing has resulted in an optimum fibre balance and density for unmatched strength.

- Treatment: A specialised surface treatment plays a critical role in extending the product life, boosting grip and reducing abrasion in stress areas.

Release lanyard in ‘gripping’ position

Release lanyard in ‘open’ position

Structural integration model

Release lanyard knob